Reducing Weight, Maintaining Strength

Engineers consider aluminium a consistent product in reducing weight whilst maintaining strength.

Whilst aluminium does not provide the best strength-to-weight ratio of all alloys, it is more stable than products such as magnesium and is also 2.5 times less dense than steel.

Adaptability is another obvious benefit since both heat-treated and non-heat-treated versions offer different options. Essentially aluminium gives design engineers options to improve performance whilst reducing weight. Aluminium is a highly versatile engineering alloy which provides excellent corrosion resistance, while resistance may be improved further by painting or anodising.

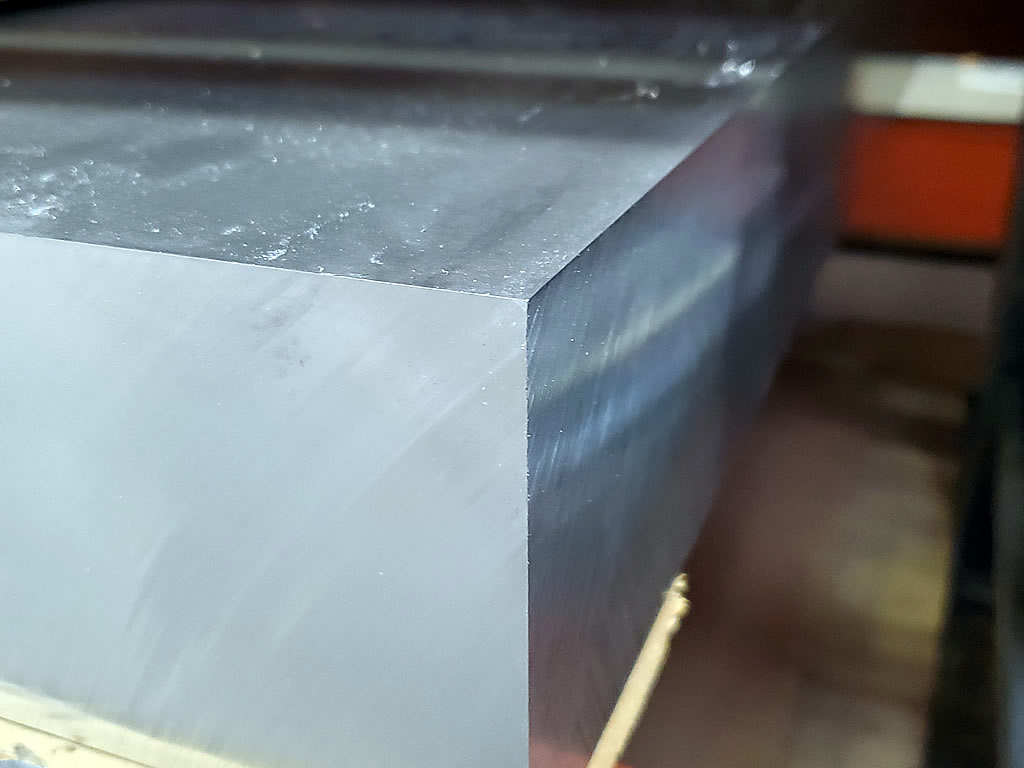

Outstanding corrosion resistance, high strength, good ductility and excellent machinability are all positive characteristics of aluminium alloys.

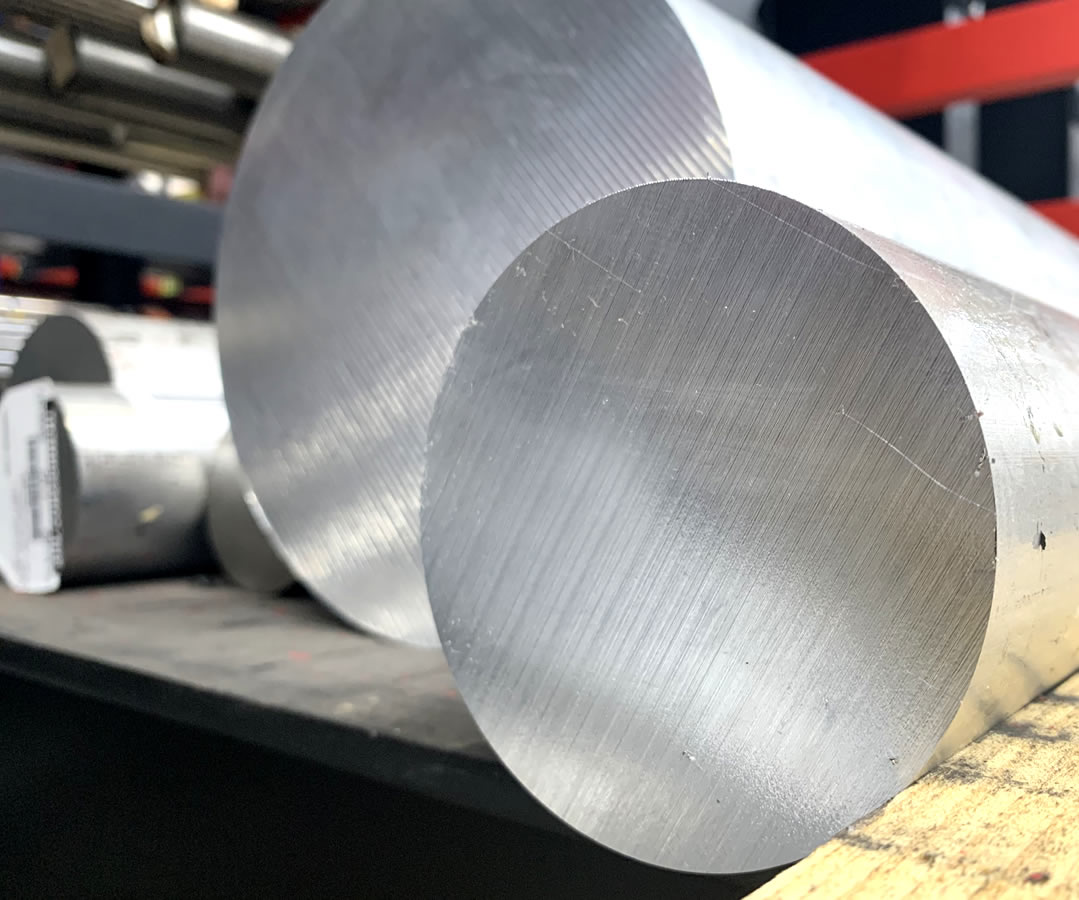

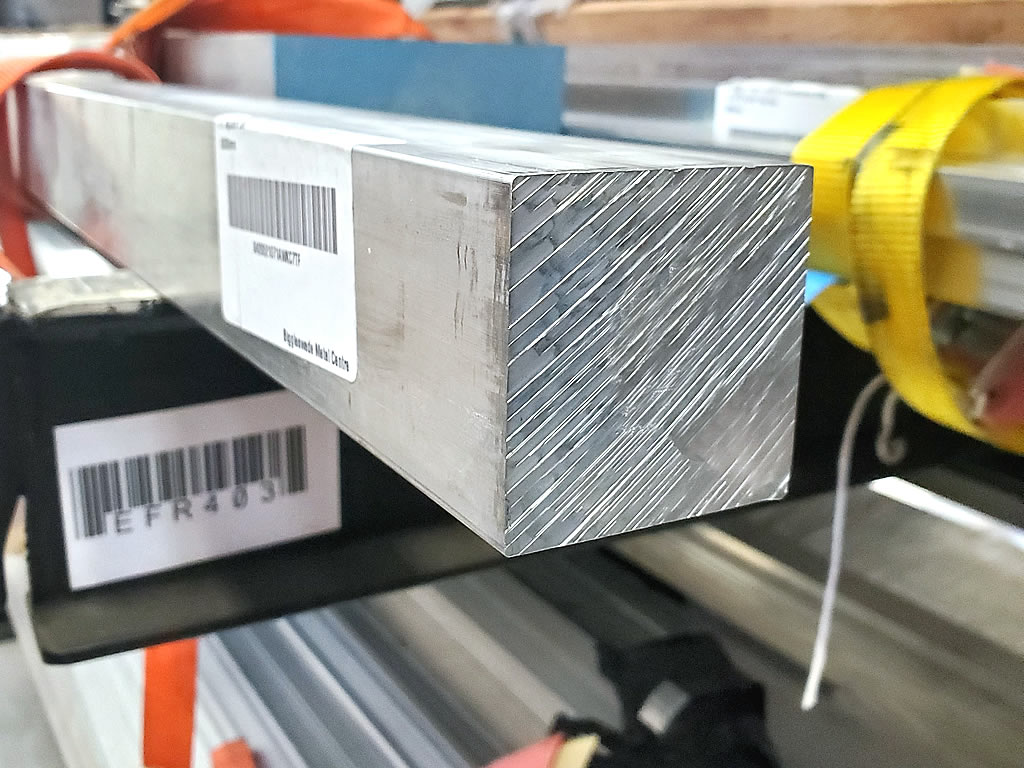

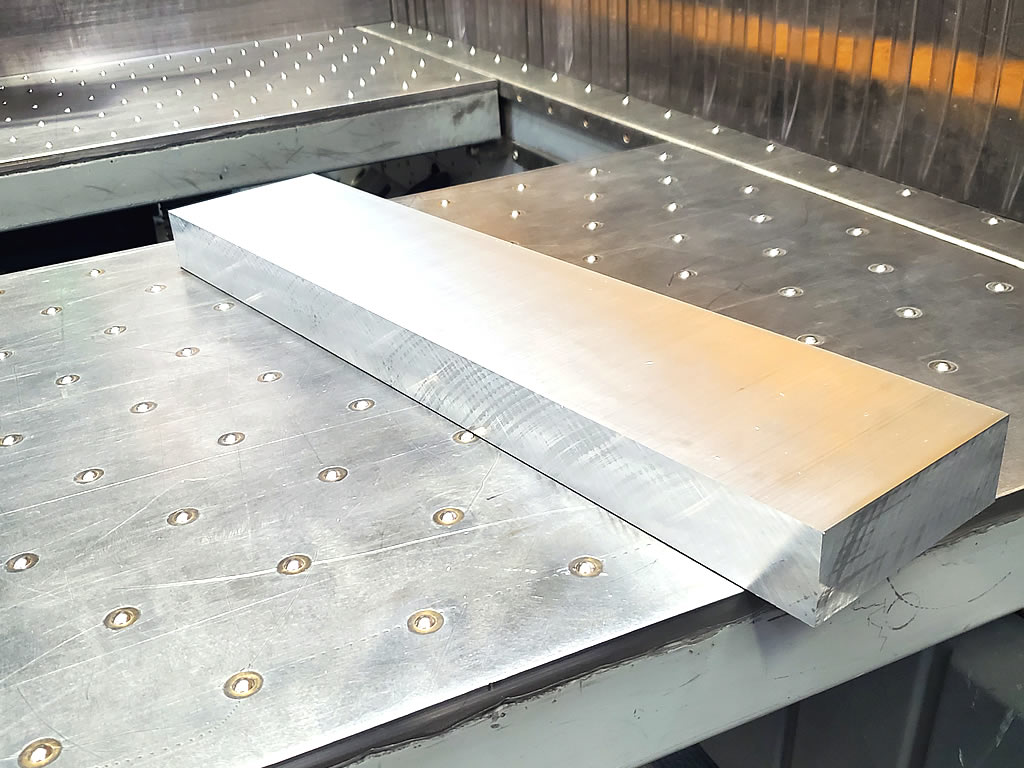

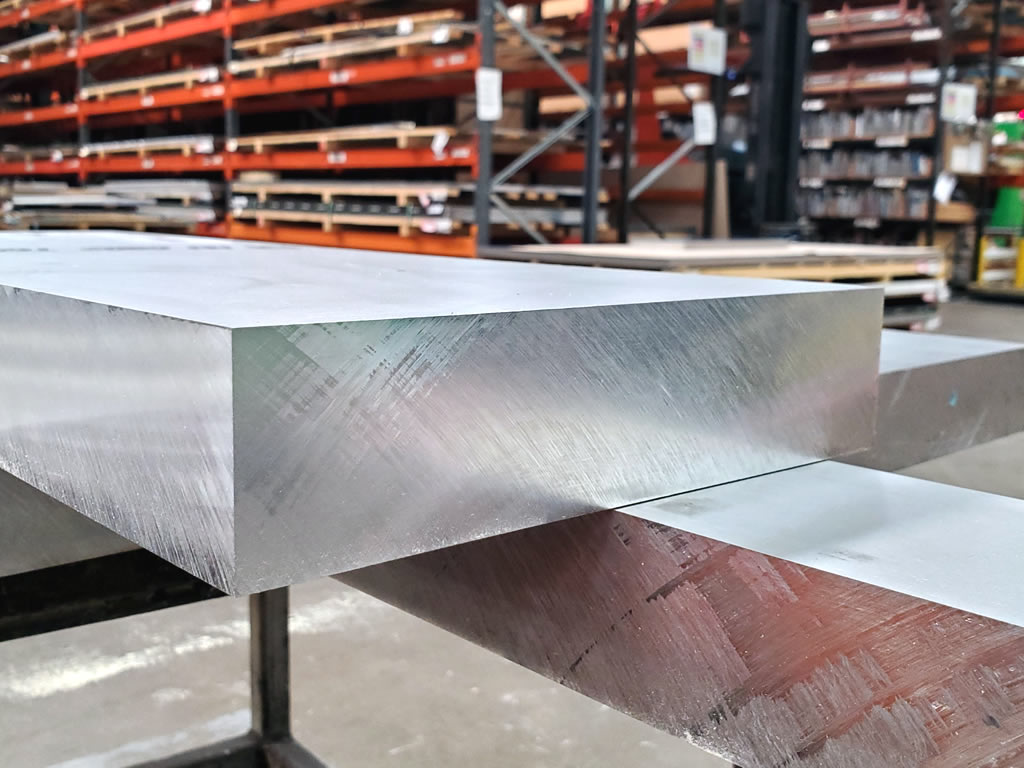

We stock aluminium products in various forms, including bars, sheets, plates and tubes.