6026 Aluminium

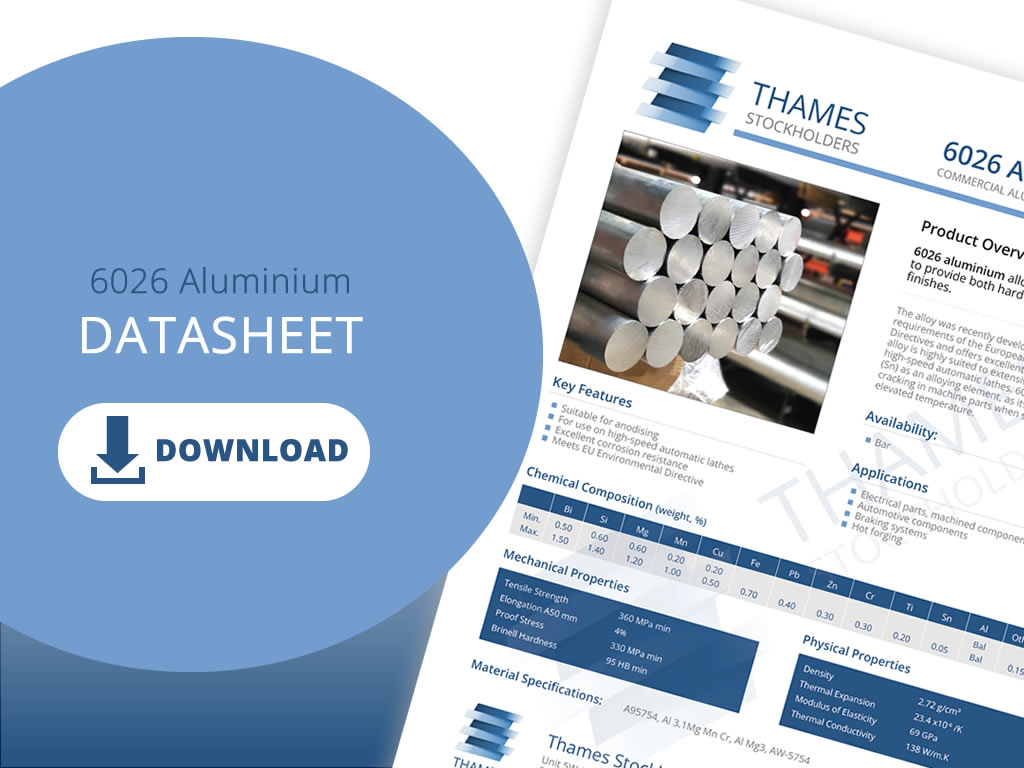

6026 aluminium alloy is suitable for anodising to provide both hard anodised and decorative finishes.

The alloy was recently developed to meet the requirements of the European Environmental Protection Directives and offers excellent corrosion resistance. The alloy is highly suited to extensive machining with high-speed automatic lathes. 6026 does not contain tin (Sn) as an alloying element, as its inclusion can cause cracking in machine parts when subjected to stress and elevated temperature.

Benefits:

Typical commercial applications include:

- Suitable for anodising

- For use on high-speed automatic lathes

- Excellent corrosion resistance

- Meets EU Environmental Directive

Machining

6026 aluminium often replaces 6082 and 6081, especially when producing finished parts on high-speed automatic lathes. When machining, the material makes tightly curled chips while benefiting from rapid metal removal rates. All these factors combine to make the alloy a highly efficient engineering alloy to machine at high speeds.

High Performance

All alloys represent some form of compromise. However, 6026 aluminium boasts performance capabilities which are better than most. Such capabilities include good workability, excellent hard anodising capabilities, superior weldability and excellent high-speed machining characteristics. Add to this superb corrosion resistance, and we have a product that suits a broad range of commercial applications.

Availability

We stock 6026 aluminium alloy in round bar.

Related Specifications

A95754, Al 3.1Mg Mn Cr, Al Mg3, AW-5754

Product Summary

| Product | 6026 Aluminium |

|---|---|

| Type | Commercial Aluminium |

| Availability | Bar |

| Benefits | Suitable for anodising, for use on high-speed automatic lathes, excellent corrosion resistance, meets EU Environmental Directive |

| Applications | Electrical parts, machined components, automotive components, braking systems, hot forging |

| Datasheet | 6026 Aluminium - Technical Datasheet |

| Reference | Home/ Products/ Aluminium Alloys/ 6026 |