Common Uses

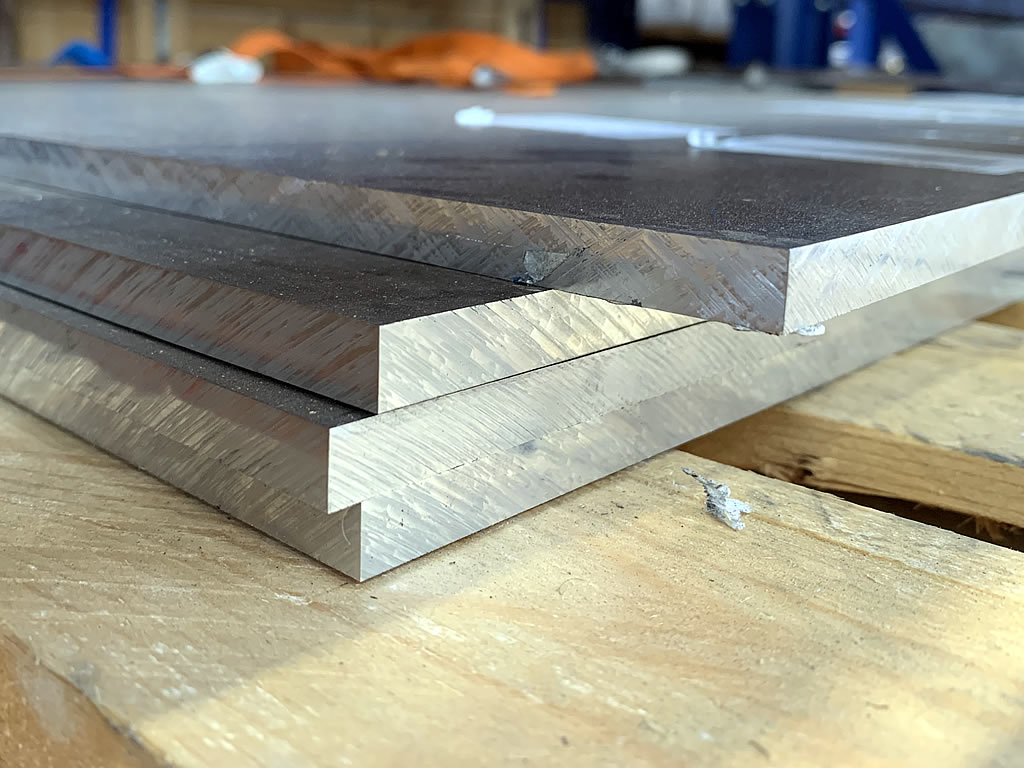

Stainless steel is an attractive engineering material due to its numerous qualities. High strength, corrosion resistance, low maintenance and cleanability make the alloy highly usable in commercial engineering applications.

The catering industry and clean room environments benefit significantly from stainless steel since the material is solid and durable while easy to clean. Stainless is also the 'go-to' product for manufacturing knives, saucepans and countertops. The material is easily sterilised, making it highly suitable for medical applications.

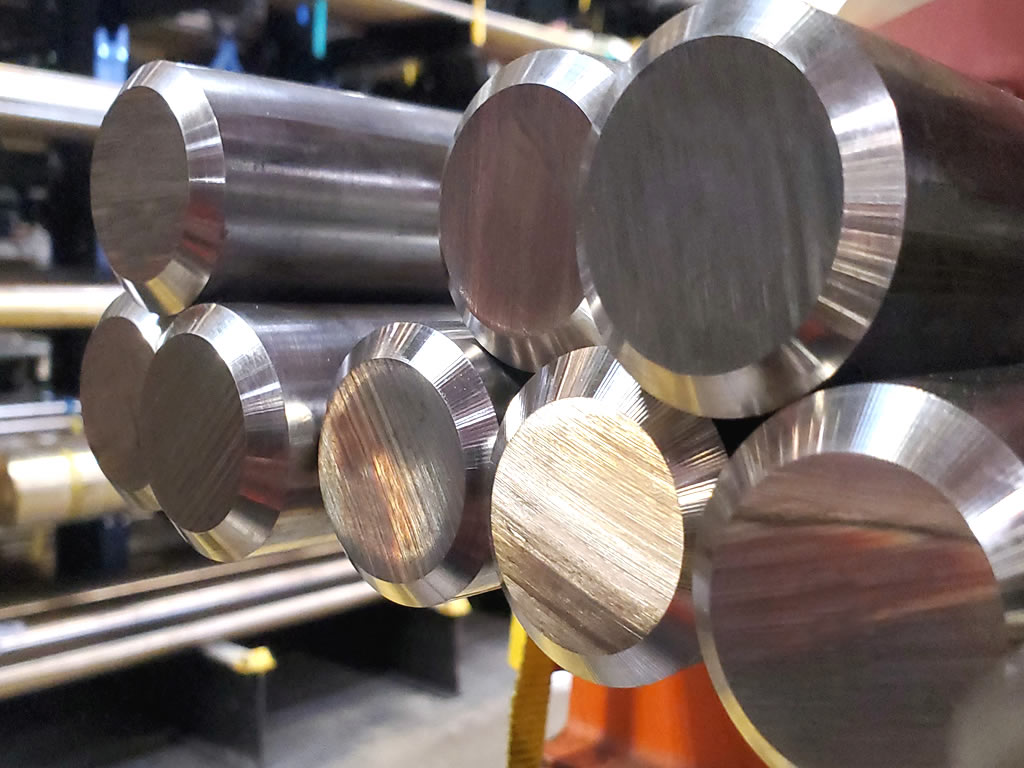

The automotive and aerospace sector also effectively uses stainless steel to produce trims, engine components, exhausts, landing gear and structural joints. Many stainless steel grades are aerospace specific or developed for this market.

Corrosion resistance also plays a significant part in how stainless steel finds use. The oil, gas and petrochemical sector uses the material to produce pipelines, heat exchangers, pressurised vessels and connectors. Any corrosion-resistant application could benefit from the use of this alloy.

The versatility of stainless steel makes it an attractive engineering material for a broad range of markets.