Alloying Elements

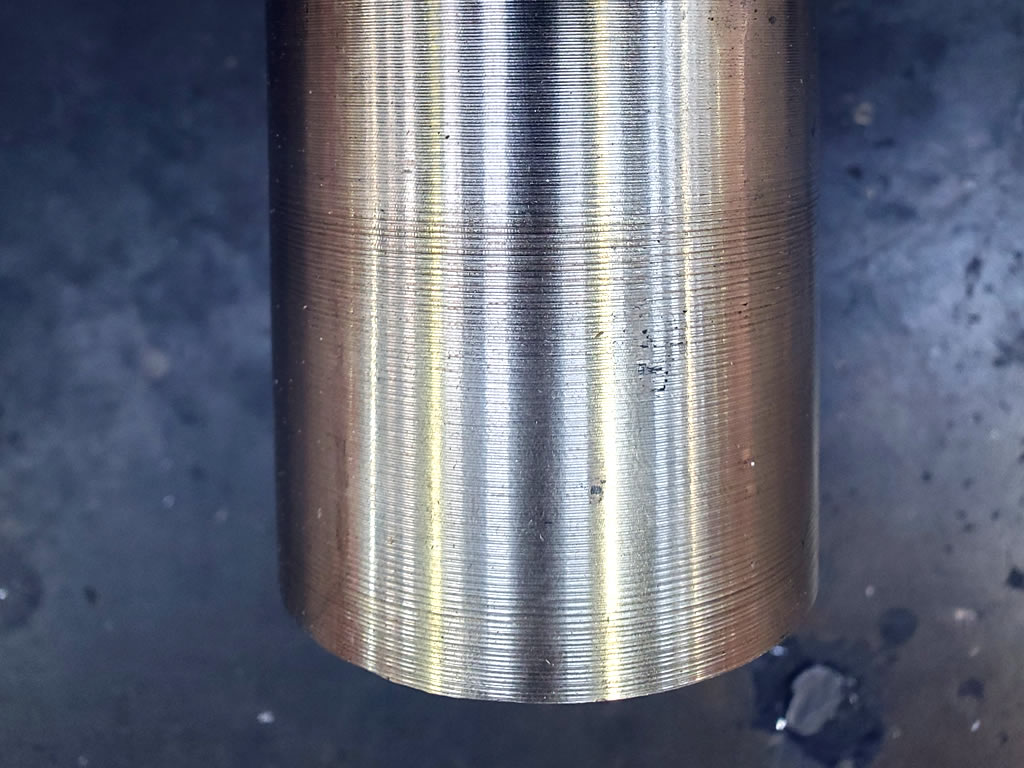

Introducing small additions of certain elements in the alloying process changes the brass alloy's performance.

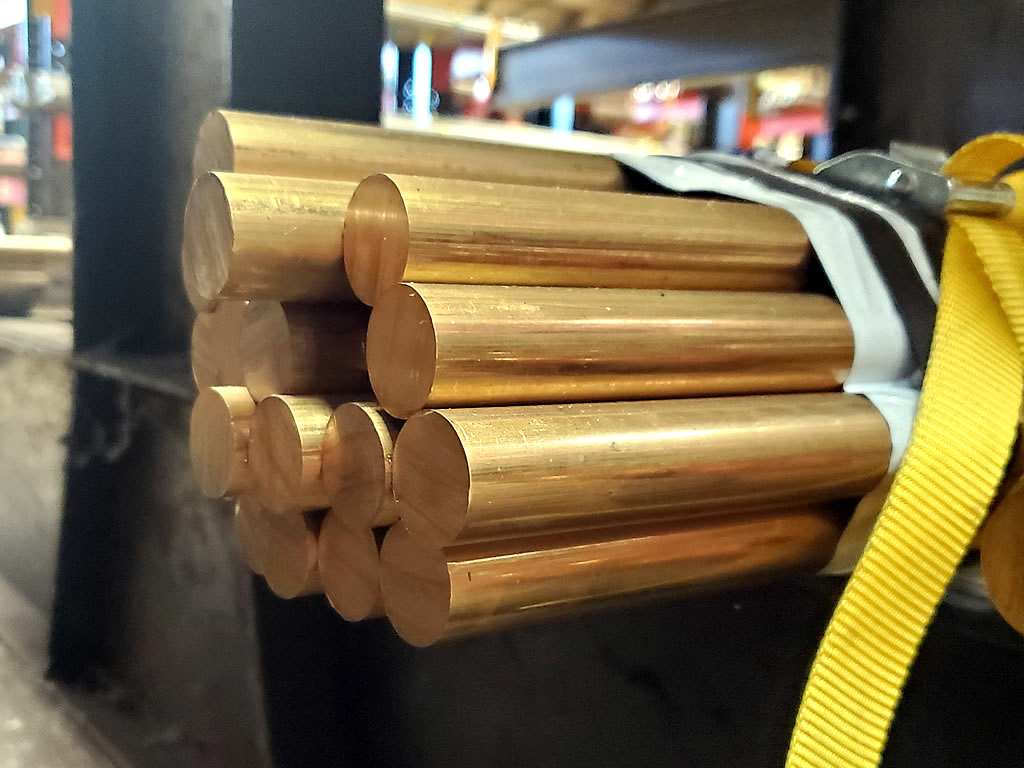

Including aluminium, tin and arsenic in the alloying process creates a product with superior corrosion resistance. Aluminium, iron, manganese, and silicon increase hardness and strength.

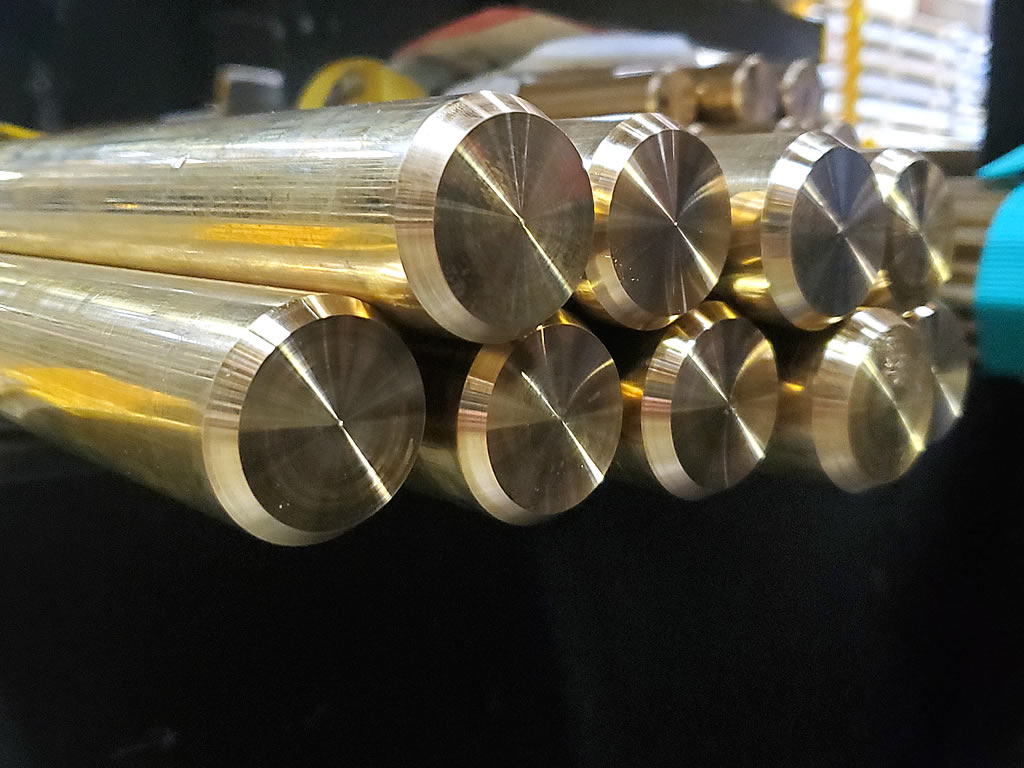

Specific grades contain increased lead content (Pb), resulting in free-machining alloys. Free-machining brass alloys are suitable for high-volume production on automatic lathes.

The intended application dictates the brass alloy required. Some customers need brass with excellent machinability, while others may focus on strength and corrosion resistance. Like all alloys, material suitability is often a compromise.

A minor modification of the chemical composition of the alloy impacts how the material performs.