2011 Aluminium

Known as an 'FMA' alloy (or free machining alloy), 2011 aluminium offers excellent general machinability and is suitable for automatic lathes.

The material's corrosion resistance is poor, so we recommend anodising, which offers additional surface protection. The alloy represents a highly versatile material that effectively produces intricate, complex parts. In such instances, welding is not required, which is fortunate since the alloy suffers from poor overall weldability.

Benefits:

Typical commercial applications include:

- Excellent machinability

- Can produce highly complex, detailed parts

- Suitable for use on automatic lathes

- Poor corrosion resistance - anodising may be needed

Suitability

2011 lends itself well to engineering applications requiring repetitive machining and may replace free-machining brass alloys without needing tooling changes.

Corrosion Resistance

Overall corrosion resistance is poor, so anodising may be necessary if protection is required. 6269 aluminium in the T9 temper may be a viable alternative if better corrosion resistance is a prerequisite.

Chemistry

Copper (Cu) and lead (Pb) are added in the alloying process, improving the machinability and strength of the resulting product. Such improved machinability and strength come at a cost in the form of reduced corrosion resistance.

Availability

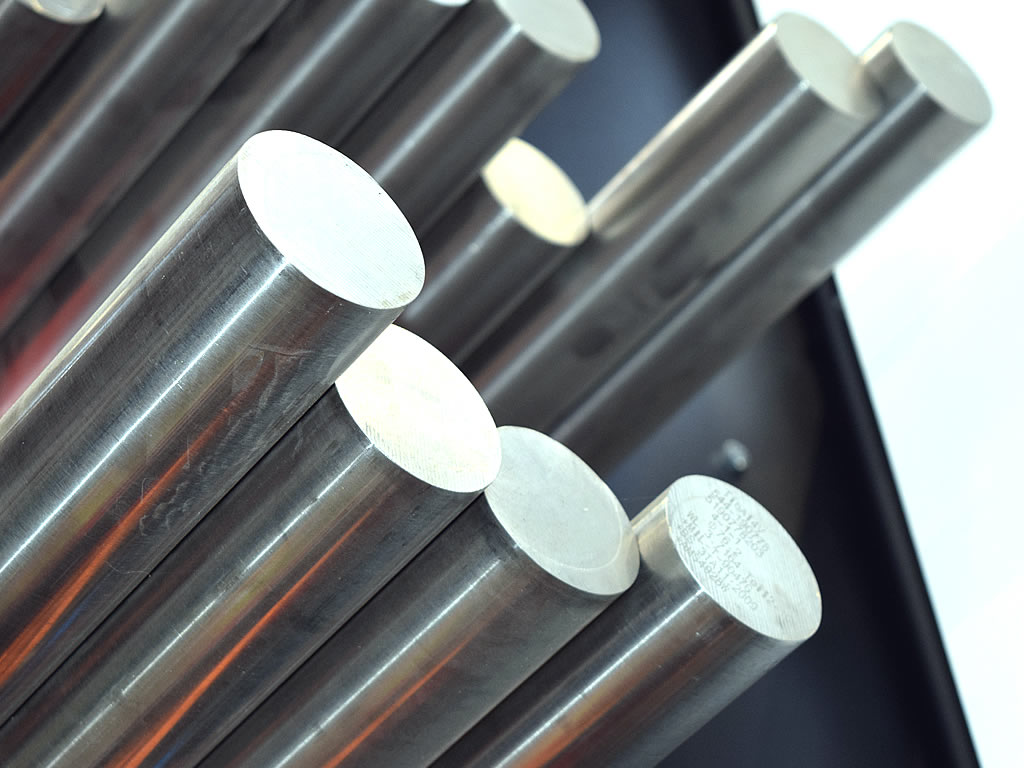

We stock 2011 aluminium alloy in round bars, which we also process in-house courtesy of our dedicated billeting services.

Product Summary

| Product | 2011 Aluminium |

|---|---|

| Type | Free Machining Aluminium |

| Availability | Bar |

| Benefits | Excellent machinability, can produce highly complex, detailed parts, suitable for use on automatic lathes |

| Applications | Automotive components, machined parts, fasteners and fittings, weapons and munitions |

| Datasheet | 2011 Aluminium - Technical Datasheet |

| Reference | Home/ Products/ Aluminium Alloys/ 2011 |