416 Stainless Steel

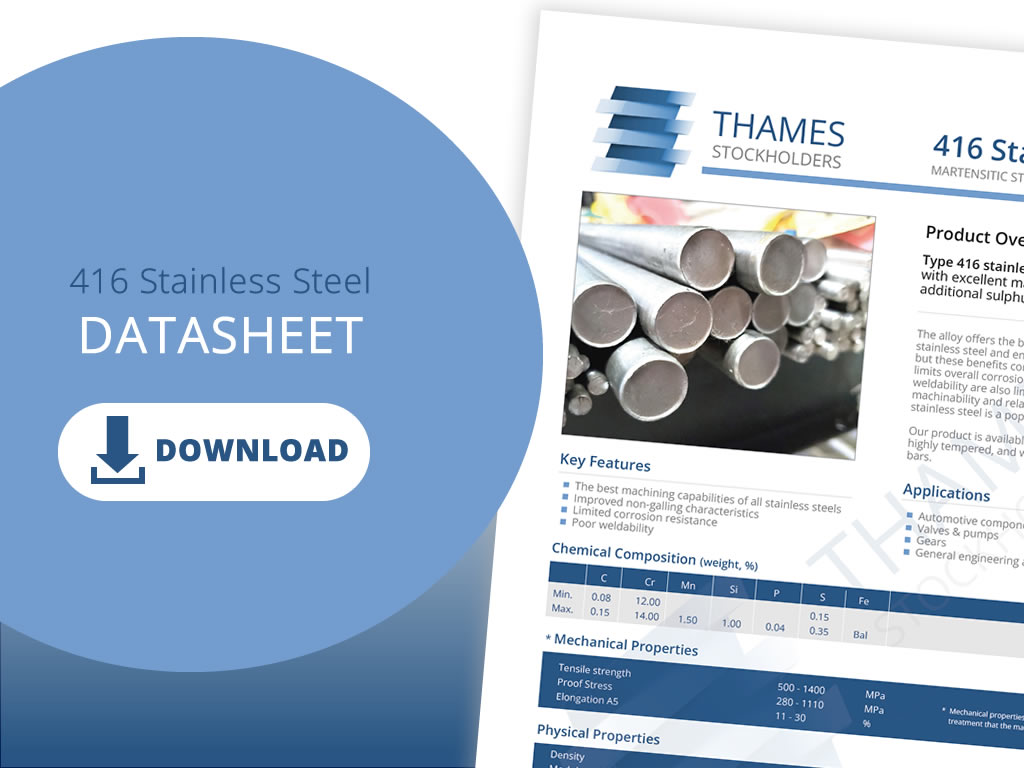

Type 416 stainless is a martensitic alloy steel with excellent machining capabilities thanks to additional sulphur in the alloying process.

The alloy offers the best machining capabilities of any stainless steel and enhanced non-galling properties too, but these benefits come at a cost. The added sulphur limits overall corrosion resistance, and formability and weldability are also limited. However, with such high machinability and relatively low material cost, 416 stainless steel is a popular engineering raw material.

Benefits:

Typical commercial applications include:

- The best machining capabilities of all stainless steels

- Improved non-galling characteristics

- Relatively low cost

- Available hardened, unhardened and highly tempered

410 vs 416

416 stainless is similar to 410 but includes more sulphur in the alloying process, providing superior machinability. Such superiority comes at the expense of corrosion resistance which is reduced. Apart from such differences, the materials are relatively identical in chemical composition and performance.

Processing

We provide in-house processing services where we cut your materials to your size requirements. There is no need to keep and manage bar stock in full lengths.

Applications

416 stainless steel alloy finds use in various engineering applications, including automotive components, valves & pumps, gears and general engineering applications.

Stock Availability

416 stainless steel alloy is available unhardened, hardened and highly tempered, and we stock the product in solid round bars.

Product Summary

| Product | 416 |

|---|---|

| Type | Martensitic Stainless Steel |

| Availability | Round bar |

| Benefits | The best machining capabilities of all stainless steels, improved non-galling characteristics |

| Applications | Automotive components, valves & pumps, gears, general engineering applications |

| Datasheet | 416 - Technical Datasheet |

| Reference | Home/ Products/ Stainless Steels/ 416 |