410 Stainless Steel

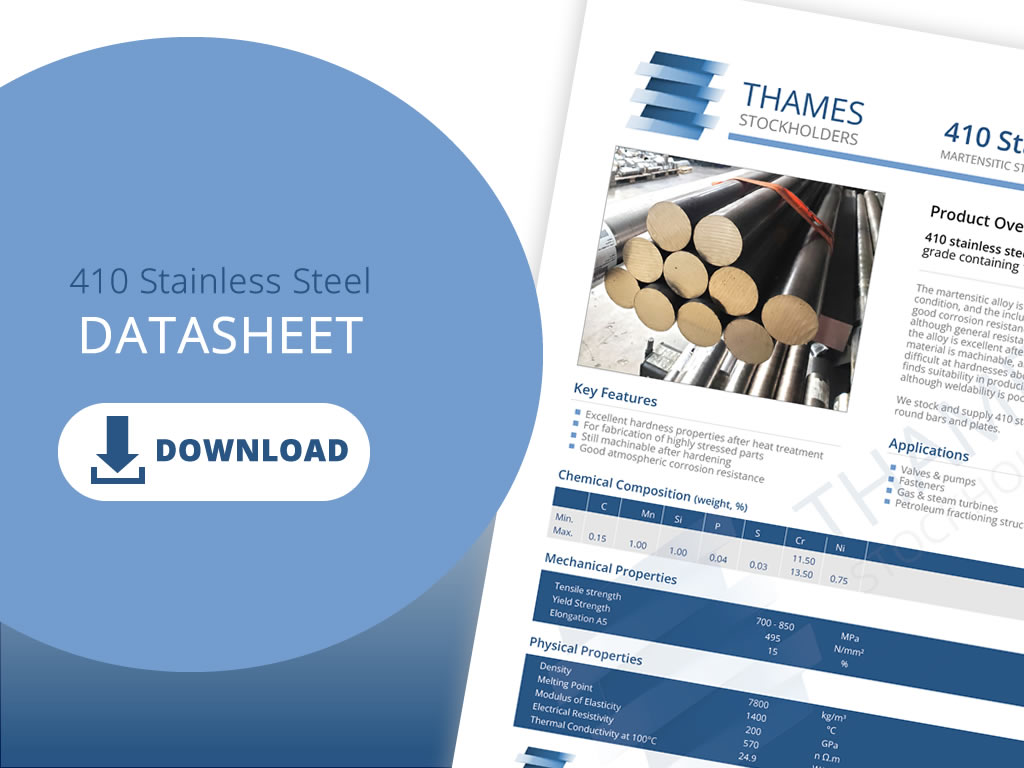

410 stainless steel alloy is a popular material grade containing 11.5% chromium and offers numerous possibilities after hardening.

The martensitic alloy is supplied in the hardened condition, and the inclusion of chromium gives the alloy good corrosion resistance under atmospheric conditions, although general resistance is limited. The hardness of the alloy is excellent after heat treatment and the material is machinable, although this proves more difficult at hardnesses above 30HRC. 410 stainless steel finds suitability in producing highly stressed parts, although weldability is poor.

Benefits:

Typical commercial applications include:

- Excellent hardness properties after heat treatment

- For fabrication of highly stressed parts

- Still machinable after hardening

- Good atmospheric corrosion resistance

Applications

We supply 410 stainless steel alloy, which finds use in applications including valves & pumps, fasteners, gas & steam turbines and petroleum fractioning structures.

Peformance

While the alloy's corrosion resistance is not as effective as austenitic stainless steels, 410 will perform well in mildly corrosive atmospheres. The material is considered a martensitic stainless steel alloy for general engineering purposes, with further performance enhancement if hardened or tempered.

Hardness

The impressive hardness of the alloy after heat treatment lends itself to the production of high-stressed parts, particularly in the oil, gas and petrochemical sectors. 410 stainless is straightforward to machine in the annealed or tempered condition but is more difficult if harder than 30HRC.

Availability

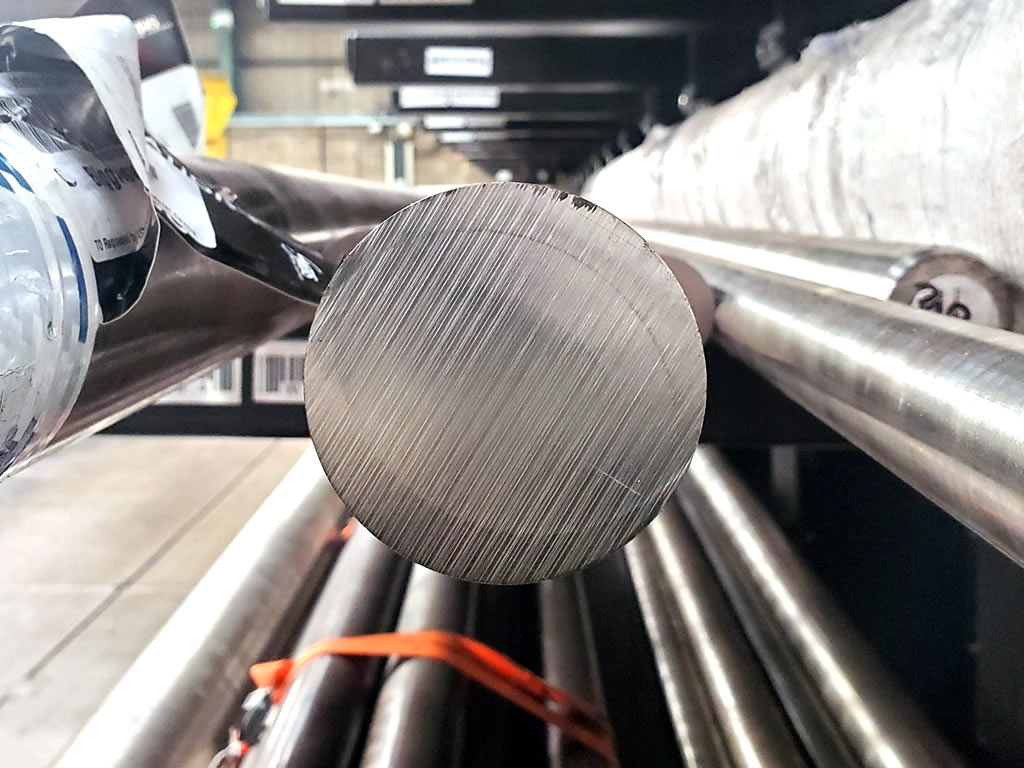

We stock and supply 410 stainless steel alloys in solid round bars and plates.

Product Summary

| Product | 410 |

|---|---|

| Type | Martensitic Stainless Steel |

| Availability | Round bar and plate |

| Benefits | Excellent hardness properties after heat treatment, for fabrication of highly stressed parts, still machinable after hardening, good atmospheric corrosion resistance |

| Applications | Valves & pumps, fasteners, gas & steam turbines, petroleum fractioning structures |

| Datasheet | 410 - Technical Datasheet |

| Reference | Home/ Products/ Stainless Steels/ 410 |